Elevate Your Product with Our Comprehensive Box Build Solutions

Elventive’s Workflow for Providing Reliable Box Build Assembly

Elventive’s box build services provide businesses with dependable solutions that align with their complicated demands, from prototype builds to full system integration.

Introduction

Elventive always aims for providing smooth integration of components into fully functional devices through our box build services that correspond to OEMs' exact specifications. The following crucial steps are included in the assembly process, which covers anything from simple assemblies to extensive systems:

The Upside of Sourcing from Trusted Box Build Experts

Elventive provides several distinct benefits that guarantee your product is successfully introduced to the market:

Customization

Box builds designed just for you. Customize every detail—from sub-assemblies and enclosures to wire harnesses and meet your unique technical requirements.

Scalability

Adapting to demand fluctuations is never a problem with Elventive. Whether the order is large or small, our box build services scale upto the exact proportion that will support your production requirements.

Comprehensive Testing

Thorough testing for reliable performance. Every unit undergoes rigorous electrical safety checks, AOI, functional testing, and more to ensure error-free operation before delivery.

Cost Efficiency

Fewer suppliers, fewer headaches. Our end-to-end services reduce complexity and cut costs, making the entire process more efficient and budget-friendly.

End-to-End Integration

All the pieces, perfectly fit together. From PCB assembly to final enclosure, we handle everything by delivering a complete, ready-to-install product.

Supply Chain Optimization

One point of contact, zero delays. With consolidated vendor management, we ensure efficient, on-time delivery of all components, streamlining the entire supply chain.

Process Overview

1. Kitting

PCBs, cables, accessories, enclosures, screws, and fasteners are among the necessary parts and materials that are gathered to ensure assembly readiness.

2. Sub-assembly

The final build is preceded by the assembly of smaller modules and parts, including wire harnesses, drives, and power supplies.

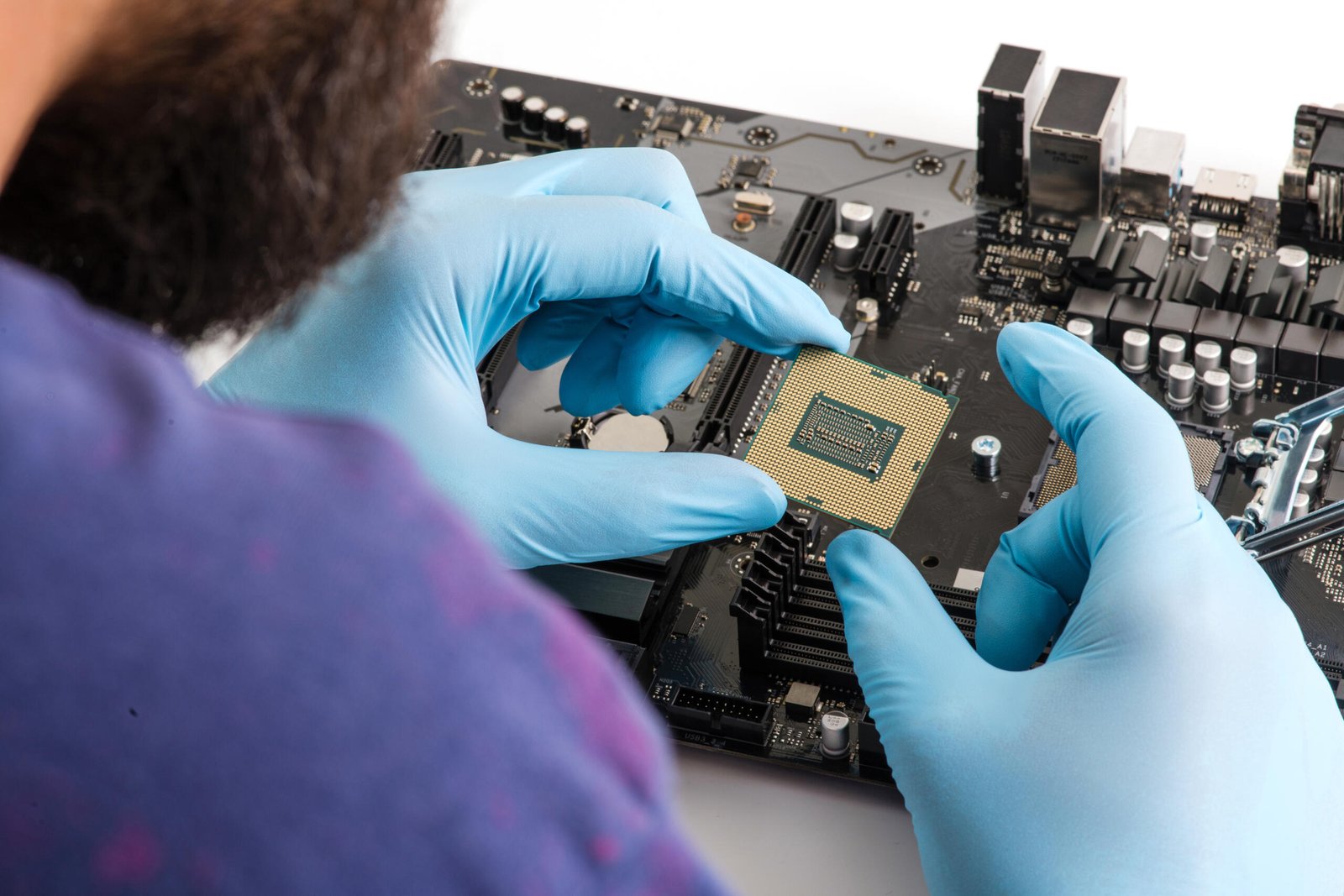

3. Product Assembly

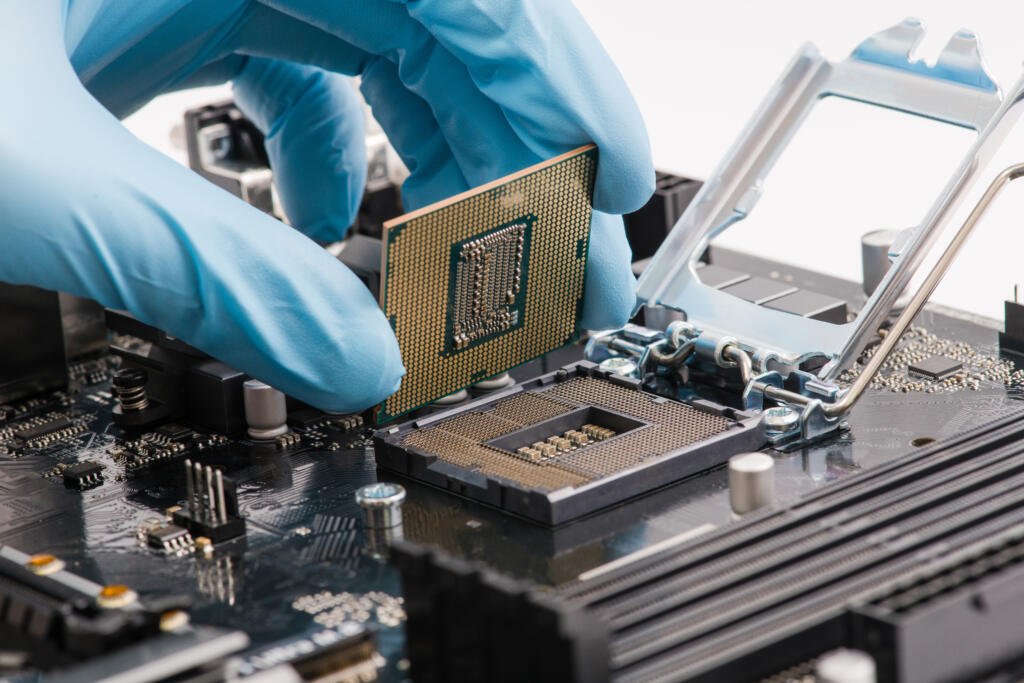

Standoffs, screws, or adhesives are used to mount PCBs and other electronic components into enclosures, and cables and wires are used to connect them.

4. Integration

The enclosure is finished by adding extra parts like keypads, handles, and brackets.

5. System-Level Assembly

Every component and module works together to create a system that is completely operational.

6. Testing

Functional, final, environmental, and burn-in testing are among the rigorous quality assurance tests that are carried out to confirm performance, safety, and regulatory compliance.

7. Software Loading and Configuration

The product configuration is completed and the required software is loaded to guarantee correct operation.

8. Warehousing & Order Fulfillment

Products are tracked, kept in inventory, and ready for order fulfillment to guarantee on-time delivery.

9. Packaging & Labelling

The product is carefully packaged, labelled, and barcoded, with user manuals included, ensuring readiness for shipment.

10. Aftermarket Services

After delivery, ongoing assistance and services are offered to guarantee the product’s continued dependability and functionality.

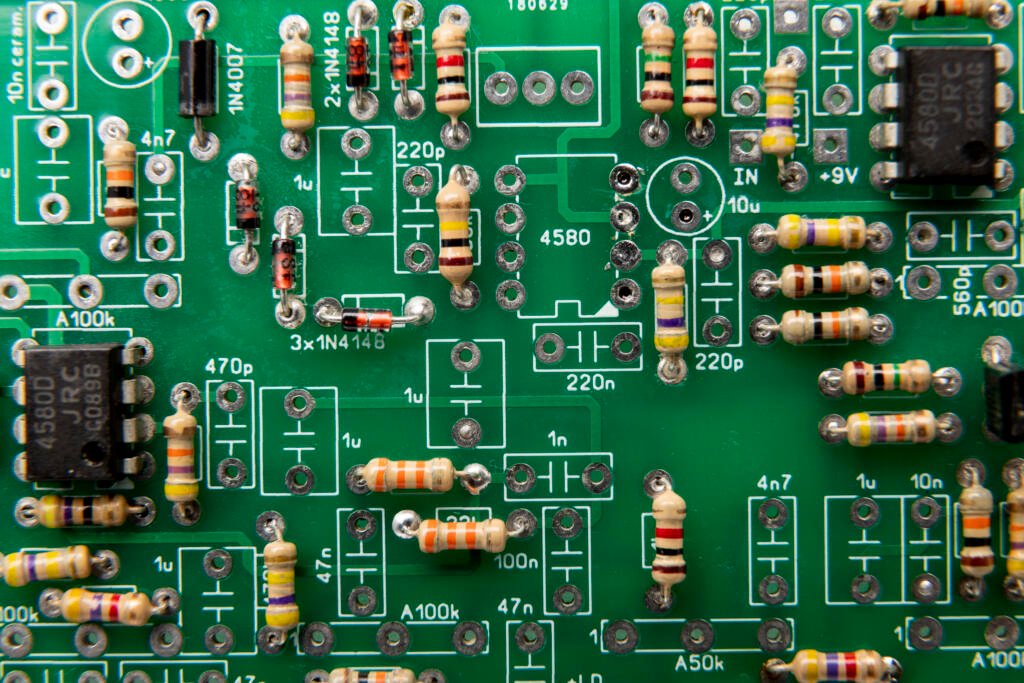

Technology Used in Box Build Assembly

Elventive’s box build services are powered by the use of modern technology. Such a standard of work guarantees accuracy, dependability, and uniformity in every undertaking. A summary of the involved technologies is as follows:

For box builds involving PCB integration, SMT lines can mount electronic components with high precision, ensuring rapid and accurate production.

Reflow soldering is used to bond components securely to the PCB. With 7-zone temperature control, this oven ensures consistent results, critical for the integrity of high-performance electronic systems.

For through-hole components, our conveyorized insertion line offers precision and speed, which is particularly important in more complex box builds that include larger, more durable components.

Automated Optical Inspection systems verify whether high-density printed circuit boards are devoid of flaws. This technology conducts thorough examinations to ascertain the precision and quality of each PCB fabrication prior to final assembly.

Our facilities have ESD protection to safeguard sensitive electronic components during assembly, ensuring the involved goods are protected from electrostatic discharge.

Take the Next Step with Elventive’s Box Build Services

Managing complex supply chains, ensuring quality control, and meeting industry standards can be exhausting for businesses, without a safeguarding element in place. Elventive’s box build services tackle these issues directly, offering solutions that can meet the industry standards.Get in touch with us today to learn about how our expert box build can restructure your product development and deployment process. Shorten time to market and the associated success, only with Elventive.

FAQ

1. What is the difference between PCB and box build?

A printed circuit board (PCB) focuses on assembling and wiring electronic components, while a box build assembly involves integrating the PCB with other elements such as cables, connectors, and enclosures. Box build services involve a broader scope of operations, including wiring, sub-assemblies, and mechanical assembly, while a box build PCB is only a part of the entire system. The key distinction is that PCB manufacturing is component-focused, while box build handles the complete product, covering aspects like system integration and final packaging.

2. What are box builds used for?

Box build assemblies are utilized to create complete electromechanical systems that house PCBs, cables, and other critical components in a protective enclosure. These assemblies streamline the final stages of product manufacturing by integrating all elements into a finished unit. Box build services include testing, integration, and packaging, serving industries like telecommunications, medical devices, and automotive electronics. Box build assembly companies ensure that the final product meets all technical and mechanical specifications before delivery, covering everything from system integration to quality assurance.

3. What is a PCB box?

A box build PCB refers to a protective enclosure or casing used within the box build assembly to house a printed circuit board. The purpose of the PCB box is to shield the involved PCB from environmental factors, such as dust, heat, and moisture, while providing structural integrity. Through box build services, businesses can create a PCB box associated with an easier workflow for system integration. On an industry-wide note, box build assembly companies design these enclosures based on size, material, and thermal requirements.

4. What is a box used for?

In the context of box build assembly, a box is used to enclose and protect the internal components of an electronic system, such as the box build PCB, wiring, and other sub-assemblies. It ensures the safety and functionality of the device by offering mechanical protection and providing a window for easy integration of various components. Box build services customize these enclosures to meet specific size, material, and environmental requirements. To guarantee dependable operation in real-world applications, the box is an essential component of the product's final packaging.

5. What are the two types of boxes?

In box build assembly, two primary types of boxes are often used: rigid and flexible. Rigid enclosures, generally made of metal or hard plastic, offer protective covering for internal components, including the box build PCB and wiring. Flexible boxes, made from materials like soft plastics or polymers, are used where space or weight constraints exist. With the help of Box build services, businesses can select the appropriate type based on application requirements, with box build assembly companies offering solutions depending on the mechanical, thermal, and environmental demands of the product.

6. What is the box construction method?

The box build construction method involves assembling and integrating a wide range of components within a protective enclosure. It starts with the installation of the box build PCB, followed by wiring, sub-assembly integration, and final mechanical assembly. The process includes testing for functionality and ensuring compliance with safety standards. If you rely on Box build services for the same construction, they involve thermal management, grounding, and shielding considerations within their workflow. Box build assembly companies focus on efficient methods for both low and high-volume production, using automation and custom design to optimize the process.