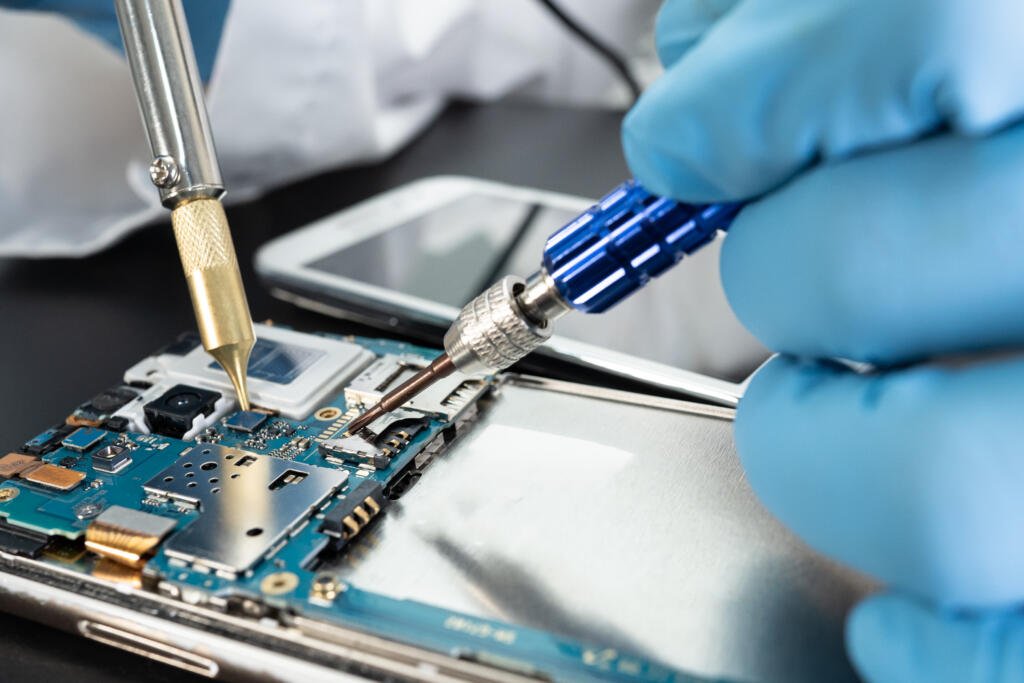

PCB Design Services for Reliable & Efficient Electronic Products

Effective Product Development With Advanced PCB Design Company in India

Printed Circuit Board (PCB) design is a fundamental aspect of every electronic device’s development. It creates a detailed plan of the board’s physical structure & electrical pathways which allows the device to function as intended. A proper design framework is essential during new PCB development, particularly when transitioning from concept to production. This framework helps to improve performance standards, reduce operative interference & ensure the manufacturability of the design at hand. Engineers at our PCB design company in India use their strategic processes to verify if the product’s circuitry is operating correctly & efficiently under real-world conditions.

Introduction

Since 2021, Elventive has been providing PCB design services in India & assisted businesses across multiple sectors in terms of developing durable electronic products. As newer electronics products come along with better energy-efficient designs with improvised operational parameters, PCB designs are expected to support higher-speed circuits, denser component placements & increased functionality.

As compared to new PCB designing companies in India, Elventive is an entity that has been most intuitive about acknowledging that - the successful usage of any electronic device largely depends on the accuracy & efficiency of the PCB design involved.

Our Services

PCB Layout & Design

PCB layout design involves arranging the components on the PCB and defining the electrical connections between them. The layout must take into account signal routing, layer stacking, and physical constraints to ensure the device meets its performance and reliability goals. In modern PCB designs, high-density layouts are common, which require multi-layer boards to handle complex electrical paths. Collaborating with new PCB designing companies in India can provide innovative solutions and fresh perspectives on complex design challenges.

High-Speed PCB Design

High-speed PCB design is crucial for applications that involve high data transfer rates, such as networking equipment, high-performance computing, and medical devices. New PCB design companies often excel in these designs, where signal integrity becomes a significant factor, requiring careful management of signal rise times, trace lengths, and power distribution. A reputable PCB design company in India can provide the expertise needed for high-speed designs, demanding rigorous analysis of factors like signal reflections, crosstalk, and ground plane design to ensure reliable data transmission without degradation.

PCB Layout Optimization

Before a design enters production, PCB layout optimization is a crucial stage in improving it to solve any performance concerns. Engineers at our PCB Design Company in India examine the board for regions that could result in electromagnetic interference (EMI), signal noise, or excessive heat buildup through layout optimization. With PCB design services in India, businesses can save their budget on expensive redesigns & increase the overall dependability of their products by spotting & fixing these problems early in the design process.

PCB Design Process

Consultation & Requirements Gathering

Every new PCB development begins with understanding the project’s technical requirements, including electrical specifications, environmental conditions & regulatory constraints. Our network of engineers will do the needful to gather detailed information about the required PCB which will guide the entire design process down the line.

Schematic Design & Simulation

Schematic design is the first technical step, where engineers create a detailed representation of the circuit. This stage includes component selection, defining the electrical connections, and ensuring that the design aligns with the desired functionality. Many engineers seek PCB design services in India to enhance this process, utilizing simulation tools to verify the design’s performance under different operating conditions and addressing potential issues like signal loss or power distribution imbalances.

PCB Layout & Routing

Once the schematic is validated, the PCB layout process begins. This stage involves placing components on the board and routing the electrical connections. Many new PCB design companies use advanced design tools to optimize trace routing, minimize interference, and ensure that the PCB can handle the required electrical loads.

Design Review & Validation

After the layout is completed, the design undergoes a thorough review. This includes checks for design rule violations, signal integrity issues, and thermal management concerns. In new PCB development, validation tools are used to simulate the board’s performance under different environmental conditions, ensuring that the design meets the project’s reliability standards.

Prototype Development & Testing

Following design validation, a prototype is developed for real-world testing. This step allows engineers to confirm that the PCB operates as expected in its intended application. New PCB designing companies in India often excel in this stage, as prototypes are subjected to thorough testing to identify any design flaws that may not have been apparent during the simulation phase.

Production-Ready File Delivery

Once testing is complete and the design is finalized, production files are generated. These files are used by manufacturers to produce the PCB at scale, ensuring that the design can be replicated consistently during mass production. Companies offering PCB design services in India often provide comprehensive support in creating these production files for efficient manufacturing.

Technology and Equipment

PCB design is conducted using advanced CAD tools such as Altium Designer, Cadence Allegro, and other industry-standard software. These tools are crucial for creating detailed schematics, designing multi-layer PCBs, and ensuring signal integrity through simulations. New PCB design companies often leverage CAD tools to visualize and lay out the PCB while adhering to design rules that prevent issues like trace width violations or incorrect component placement.

Ensuring signal integrity is one of the primary concerns in high-speed PCB design & assembly. Tools like HyperLynx & Ansys HFSS are commonly used for signal integrity analysis, helping designers predict issues such as crosstalk, impedance mismatches & signal reflections that can compromise the reliability of high-frequency signals.

Design rule checking (DRC) is an automated process that verifies a PCB layout against predefined manufacturing guidelines. New PCB designing companies in India often utilize DRC tools to ensure that aspects like minimum trace width, clearances, and via sizes conform to the fabrication capabilities of the manufacturer, helping to prevent errors that could lead to production delays or faulty boards.

The qualities that separate our PCB designing process from other new PCB design companies include – micro-level attention during the entire project completion, thorough analysis of every PCB built & the use of advanced tools & technologies to curate the best output possible. Contact us today to get a free quote for your technical requirement & let’s begin your new PCB development with an effective designing background – Elventive.

FAQ

What is PCB design, and why is it important?

PCB design is the process of creating the layout for printed circuit boards that connect electronic components. It’s essential because a well-designed PCB ensures that the electronic device operates correctly and efficiently. Proper new PCB development helps in reducing signal interference, improving reliability, and minimizing production costs. As electronics keep on adding new modes of applications and inclusivity, precise PCB design is now an irreplaceable necessity in order to ensure the performance and longevity of the product involved.

How can I find reliable PCB design companies in India?

To find reliable new PCB design companies in India, start by researching companies with strong reputations in delivering quality designs and support. Look for a PCB design company in India that has experience in your industry, check client reviews, and explore their past projects. Many PCB design services in India also showcase their certifications and design standards, which is a good indicator of their reliability. Additionally, recommendations from industry peers or forums can help identify the best providers.

What is the typical cost of PCB design services in India?

The cost of PCB design services in India varies based on the complexity of the design, size of the board, and specific requirements like multi-layer designs or high-speed applications. Basic new PCB design services can start at affordable rates for simpler boards, while more complex designs with advanced features can cost a lot more than you might have expected. On average, the cost ranges from a few hundred to several thousand dollars, depending on the specific needs and customization required.

Do PCB design companies in India offer support for international clients?

Yes, many new PCB designing companies in India offer services and support to international clients. These companies are equipped to handle global projects and often have experience working with clients from various countries. They can provide PCB design services in India remotely, utilizing online communication tools for seamless collaboration. It is also found that - companies offering new PCB development often support different industry standards and regulations required for international projects. This approach ensures a smooth cross-border collaboration.

How long does the PCB design process typically take?

The timeline for new PCB development can heavily depend on the purpose of the design, the underlying complex circuit pattern, and the number of revisions. A simple PCB design might take a few days to complete, while a more complex board with multiple layers could take several weeks. PCB design companies in India work closely with clients to provide accurate timelines, and the process can be faster with well-defined requirements and close communication.

What are the requirements for PCB design?

The important requirements for PCB design include a clear understanding of the electronic circuit, component selection, and layout planning. Designers need schematic diagrams, mechanical constraints, and performance expectations to begin. New PCB design companies in India often require detailed technical specifications, such as desired signal integrity, thermal management, and power distribution. Additionally, the use of specialized design software and close communication with manufacturers is crucial to ensure the design is ready for production.